From March 3rd to 6th, the Dental South China 2024, an international exhibition and technical seminar on dental medical equipment, was successfully held at the Canton Fair Complex. UnionTech made a significant appearance with its new dental product, the "Fully Automated 3D Printer—D300," empowering dental applications with user-centric thinking for quality and efficiency enhancement, and driving talent value transformation and upgrade through technological innovation!

This exhibition focused on the innovative upgrade of the dental manufacturing industry, assisting the development of upstream, midstream, and downstream enterprises in the industry chain from an international, professional, and market-oriented perspective. As a leading enterprise in the additive manufacturing field, UnionTech has always been dedicated to the deep application of 3D printing technology in various fields and launched EvoDent, a sub-brand for the dental industry, in 2017. Through in-depth exchanges with domestic and international dental experts and technological innovation iterations, EvoDent now offers mature and comprehensive automated dental 3D printing solutions with a range of products including the E series, D series, and S series.

Stunning New Printer Debut

At Dental South China, UnionTech officially announced its new dental product—the Fully Automated 3D Printer D300, while also showcasing the EvoDent's S200, E230, and various specialized 3D printing materials for dentistry on site:

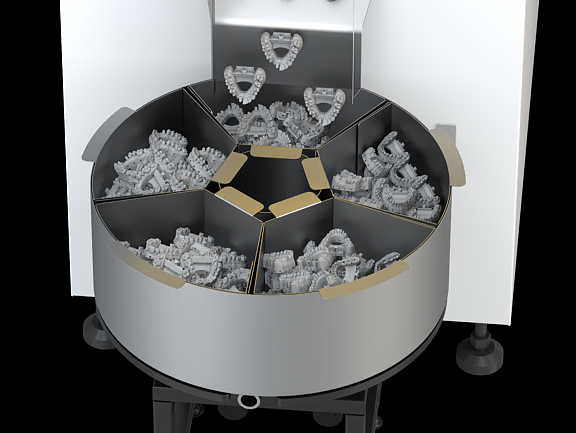

Redefining Automated Production—D300

The D300 utilizes DLP 3D printing technology and represents UnionTech's upgraded development in the field of face exposure 3D printing. It is designed for large and medium-sized denture processing factories, targeting restoration and implant model applications. It achieves automated production throughout the entire 3D printing process—from auto layout, auto queuing, and auto resin replenishing to auto printing, auto unloading, and sorting assistance—making "24/7 unmanned operation" possible and redefining the automated production model in the dental industry.

1. Intelligent Zoning, Assisted Sorting

To address pain points such as the easy confusion and sorting difficulties of dental models in daily applications, the D300 has been newly upgraded with an intelligent zoning design and equipped with a sorting assistance feature. This technological upgrade supports the simultaneous printing of various types of models and the sectional collection of printing tasks. Particularly for restorative end applications, the integrated design of models & abutments further ensures the association of complete dental models, effectively saving labor costs in post-processing. By simplifying the production process, this advancement aids in the transformation and upgrade of talent value.

2. High Automation, Stable Printing

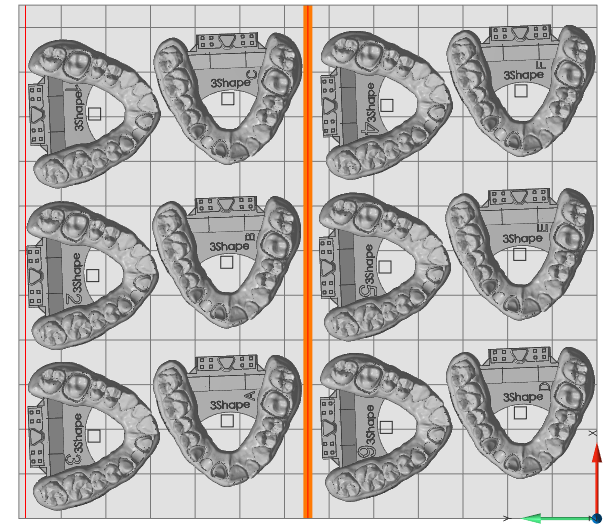

Market analysis indicates that automated production has become a main trend in dental processing. The D300 has been highly automated throughout the entire 3D printing process. It can automatically initiate tasks for continuous printing jobs, maintaining a gap change of less than 0.01mm during continuous multi-plate printing, ensuring long maintenance cycles and strong work stability. With its fully enclosed loop operation mode of auto layout, auto queuing, auto resin replenishing, auto printing, auto unloading, and auto sorting, it successfully supports users in continuous production around the clock.

3. Balanced Precision and Speed

Equipped with dual 4K projectors from above and a forming size of 258x230x120mm, the D300 achieves a new breakthrough in printing precision and speed. It can produce up to 180 dental models within 24 hours, with a precision of less than 0.07mm deviation compared to the D800, the D300 achieves 0.05mm high-precision molding. Each printing cycle is strictly controlled within 2 hours, effectively balancing speed and precision.

Empowering High-Precision Intelligent Production—S200

The S200 is a high-precision implant model 3D printer using DLP 3D printing technology. It features a design size of 192 × 108 × 200 mm, a printing speed of 40mm/h, and can print 6-12 semi-oral models at a time. Its precise optical structure, equipped with an industrial-grade 4K projector, perfectly presents excellent surface quality of dental models, providing precise and efficient digital solutions for dental clinics.

Activating Full Application Production Beside the Chair—E230

One Single Click for Diverse Applications

To provide visitors with a more tangible experience, UnionTech displayed a variety of dental models produced by 3D printing devices, showcasing the diversified applications of this technology in the dental field.

To provide you with the most thoughtful service