The fabrication of dental prostheses has always been a crucial aspect of the field of dental restoration. Traditional methods of creating dental prostheses include manual craftsmanship and CNC machining. These methods have certain limitations, such as long production cycles and lower precision. With the continuous advancement of technology, 3D metal printing has gradually been applied to the field of dental prosthesis fabrication, bringing revolutionary changes.

3D metal printing technology is an advanced manufacturing process that uses laser or electron beams to melt powder, constructing three-dimensional objects layer by layer. In the fabrication of dental prostheses, 3D metal printing can achieve highly personalized customization, with exceptionally high precision in the printed prostheses. This provides patients with more comfortable and refined oral restoration solutions.

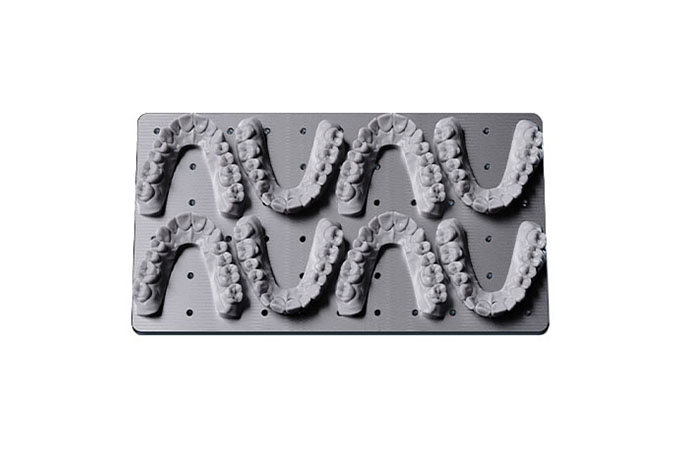

EvoDent 3D Printed Dental Model

The price of 3D metal printers for dental prostheses varies significantly depending on factors such as brand, model, and performance. Generally speaking, high-end 3D metal printers are more expensive, while mid-range and low-end printers are relatively more affordable. The specific price needs to be determined based on different needs and configurations. Market prices range from a few thousand to tens of thousands of dollars. For instance, UnionTech's E128 and E230 fall into the category of economically viable devices, making them an excellent choice for users looking for a balance between cost and performance.

EvoDent E

Compared to traditional methods of creating dental prostheses, 3D metal printing technology offers numerous advantages. First, the production cycle of dental prostheses is significantly shortened. Traditional methods may take several weeks, whereas the entire process using 3D metal printing can be completed within a few hours. Second, the precision of the dental prostheses is much higher. 3D printing technology can achieve micron-level accuracy, making the prostheses fit better in the patient's mouth, thus enhancing comfort. Additionally, 3D printing can produce complex structures, meeting the personalized customization needs of different patients.

EvoDent 3D Printed Dental Model

However, 3D metal printing technology for dental prostheses also faces some challenges. First, the cost of equipment and materials is high, directly affecting the production cost. Second, the variety of related equipment on the market is relatively limited, and the technology still requires further refinement and promotion. Lastly, the use of certain special materials still requires stringent regulation and research to ensure the quality and safety of the dental prostheses.

The development of 3D metal printing technology for dental prostheses has injected new vitality into the field of dental restoration. As the technology continues to mature and gains broader market acceptance, it is believed that this technology will provide patients with more advanced and personalized oral restoration solutions. Of course, with technological advancements, the price of 3D metal printers for dental prostheses is expected to become more reasonable, further promoting the technology's popularity and application.

To provide you with the most thoughtful service